Scientists have long known that certain types of rocks react with carbon dioxide – a process accelerated when the rock is pulverized – and can sequester it for thousands of years.

Given that that is what mine waste is – pulverized rocks – scientists with the University of BC are now working with three mining companies on demonstration projects that they say could sequester large amounts of CO2, by enhancing a natural process called carbon mineralization.

“We estimate that reacting just 10% of a mine’s waste stream could be more than enough to offset the annual carbon emissions produced by a mining operation,” said Greg Dipple, project lead and professor at the Bradshaw Research Initiative for Minerals and Mining at UBC.

UBC will work with the University of Alberta, Trent University, Institut national de la recherche scientifique (INRS) and the mining companies on two demonstration projects at mine sites in B.C. and the Northwest Territories.

One project is a prospective nickel mine in B.C. The magnesium silicate found in mine waste from metal and diamond mines will naturally fix CO2 in a process called carbon mineralization, which creates a solid, cement-like mineral. The carbon can remain sequestered for thousands of years.

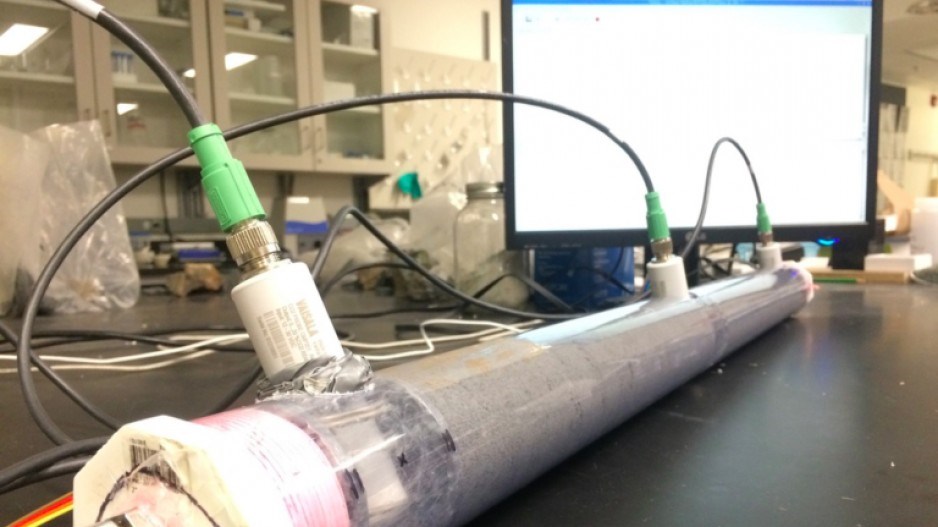

Researchers have been working on technologies that help accelerate the mineralization process.

At a mine in the Northwest Territories, CO2 will be directly captured from the mine’s power plant for mineral sequestration. In B.C., a pilot project will rely on drawing CO2 from the atmosphere. Laboratory experiments have demonstrated that the process can work fairly quickly.

“We’ve achieved rapid carbonation within days to weeks in the lab,” said Dipple. “The challenge is to reproduce this success at large volumes in the field.”

The demonstration project is being funded with $2 million from Natural Resources Canada, and another $1.2 million from De Beers Group, FPX Nickel Corp. (TSX-V:FPX), Giga Metals Corp. (TSX-V:GIGA) and Geoscience BC.

Dipple estimate that if all metal mines in the world used carbon mineralization for their mine waste, it could sequester 100 to 200 million tonnes of CO2 annually.