As Prime Minister Mark Carney’s Liberal government plans to provide billions in financing for prefabricated homebuilders, some say British Columbia is ahead of the curve.

In B.C., significant prefab efforts are already being made by government and industry. There is a task force of mayors, a precedent of using prefab for supportive housing and multiplex legislation inviting standardization.

With significant industrial capacity to boot, B.C. is ready to lead on the issue if federal dollars come flowing, said one expert.

“I think British Columbia is taking a huge approach right now,” said Paul Binotto, director of Modular BC, a non-profit advocating for the industry’s expansion.

Prefabrication is often touted as a way to accelerate construction times, improve quality control, shrink per-unit costs, reduce emissions and waste, and optimize labour. It is also said to cause less disruption to neighbourhoods due to quick installation.

According to Modular BC, factory-made housing currently accounts for approximately 4.5 per cent of new homes in B.C. each year. The organization aims to boost this to 25 per cent in the next five years by bringing together stakeholders and providing them guidance and training.

Working with partners ranging from B.C. mayors to National Research Council Canada, the non-profit is creating a “made-in-B.C. playbook” to share with other provinces.

“Anything we can do to help bring attention to [the program] and help deliver it builds a strong, strong industry. I’m all in favour of that, and I think the time is perfect for it now,” Binotto said.

When parliament began its legislative session on May 27, Carney’s government was expected to quickly begin implementing its Build Canada Homes plan, which promises, among other things, over $25 billion in financing to “innovative prefabricated home builders in Canada,” according to the party’s website.

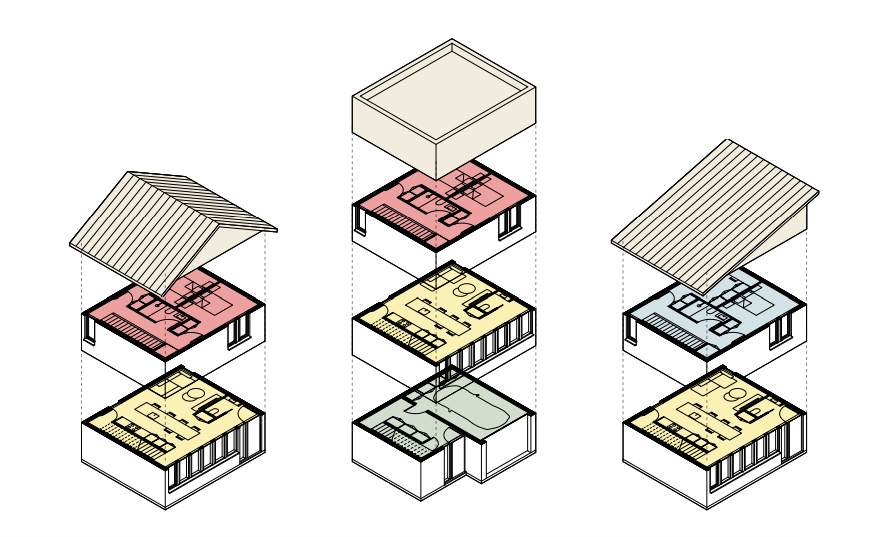

Prefabrication generally refers to any manufacturing of building components in controlled environments before they are transported for assembly. Modular construction is a subset involving the manufacture of box-like “modules” that join together easily, according to University of New Brunswick’s Off-site Construction Resource Centre.

Sometimes, an entire home is prefabricated indoors before being transported, in one piece, to its destination on a large truck.

“There’s usually a little bit of site work that’s required to button them up, but the homes are completed. They are completely closed up, they are all drywalled, complete exteriors, all the plumbing and electrical fixtures are in and operable,” said Darren Bassett, general manager with Moduline Industries in Penticton.

Business reacts to prefab promises

Bassett, whose company has built almost 30,000 modular homes over the past 55 years, reacted positively to the Liberals’ prefab plans.

“What I have heard is definitely positive and moving in the right direction, not only for modular construction and solutions but also just housing in general to appease the affordability issue,” he said.

Moduline is a division of Champion Canada Modular Ltd., which operates four modular factories in Western Canada, each with an average of 175 employees. In B.C. as a whole, there are about 18 modular home factories of various sizes and specialties, said Binotto.

A number of factors have held back the industry over the years, according to Bassett.

Concerns around quality persist, he said. Although “there’s a bit of a stigma around modular construction being more of a trailer-type construction,” he said the quality is the same as, or even better than, site-building.

He said Moduline’s products meet the B.C. and national building codes. The company also has its own internal quality program under CSA Group standards, with third-party oversight by Intertek Group PLC.

Another barrier is financing for prospective buyers, Bassett said.

“For consumers to get financing is a bit of a challenge particularly with a modular solution, even though they are more affordable,” he said.

Freight transportation of complete modular homes is also tricky, with transportation laws constraining lengths, widths and heights, he said.

Perhaps the biggest obstacle is a high barrier to entry.

“There’s a lot of capital that has to go in to start up, and a lot of overhead costs in order to keep operating. The biggest challenge is volume,” Bassett said.

“The plants need volume. Without volume, it’s difficult to overcome the overheads and the high cost of lease and city taxes and that sort of thing in order to be profitable.”

Bassett said it’s currently a “down market” and that Champion’s factories are running at roughly 25-per-cent capacity. On May 22, the company announced the closure of one of its factories, SRI Homes Kelowna, citing market conditions.

Factories are thirsty for more work to stay afloat and therefore have “massive capacity to scale up,” he said.

Province, mayors stand ready

B.C. Housing Minister Ravi Kahlon said the province looks forward to working with the federal government to advance prefabrication.

“If we want to reach the ambitious target that the prime minister has laid out … we’re going to have to build differently,” Kahlon said.

The province has been a major purchaser of prefabricated homes in the supportive housing space, enabling faster deployment, he said.

In 2017, B.C. launched the Rapid Response to Homelessness program to quickly build modular supportive housing units across B.C. for people experiencing or at risk of homelessness. The program helped build projects comprising nearly 1,900 modular supportive homes in 22 communities, all of which were completed and opened by March 2021.

More recently, B.C. released free home designs that can be prefabricated, and its multiplex legislation, Bill 44, could result in greater prefab investment and economies of scale.

“We see companies pop up, we see companies go, it’s in the early days,” Kahlon said. “A [federal-provincial] partnership could create the scale for a lot of our smaller companies to grow into dynamic companies that help address the challenges everywhere.”

At the municipal level, there’s still work to be done to ensure cities understand prefabricated homes, said Mike Hurley, mayor of Burnaby and a member of a new Mayors Task Force on the subject.

The five-member task force, created on November 22 with Modular BC, aims to streamline factory-built homes and educate city leaders across the province. Besides Hurley, it includes Prince George Mayor Simon Yu, Penticton Mayor Julius Bloomfield, Nanaimo Mayor Leonard Krog and Williams Lake Mayor Surinderpal Rathor.

“I think the role that cities can play is to ensure that we understand [prefabricated homes] first and foremost and that they get approved as quickly as possible so that we can get these flowing through the system really well,” Hurley said.

With support from Modular BC, city staff can be trained on regulating off-site homebuilding methods, he said.

“There’s always nervousness with inspectors and people in the building department about stuff like that, but I think we’ve got to a very good place now of understanding,” Hurley said.

“Cities can really start to take the lead and be fully confident that these are going to be very well-built and very well-designed.”