When the University of British Columbia’s (UBC) new student residence is completed next year, it will eclipse the eight-storey Wood Innovation and Design Centre in Prince George as the tallest wooden building in B.C.

At 53 metres, the 18-storey structure would be the tallest wooden building in Canada – possibly the world – although it will soon be overshadowed by an even taller one: the 84-metre HoHo wood skyscraper planned for Vienna.

As the world moves toward decarbonization, wood as a building material for highrises and even bridges is gaining in popularity because concrete and steel production generates a considerable amount of greenhouse gases. Moreover, wood sequesters carbon.

Tall wooden buildings are starting to go up all over North America and Europe, creating a new demand for specialized expertise in solid-wood structural engineering.

Fast + Epp and Equilibrium Consulting Inc. are two B.C. companies that have been developing expertise in this area, and the University of Northern British Columbia (UNBC) will soon be yielding engineers who specialize in solid-wood engineering, thanks to a new master of engineering in integrated wood design degree program.

Equilibrium did the engineering for the Wood Innovation and Design Centre in Prince George. Fast + Epp was one of the engineering firms that worked on the Richmond speedskating oval, which features one of the world’s largest wooden roofs.

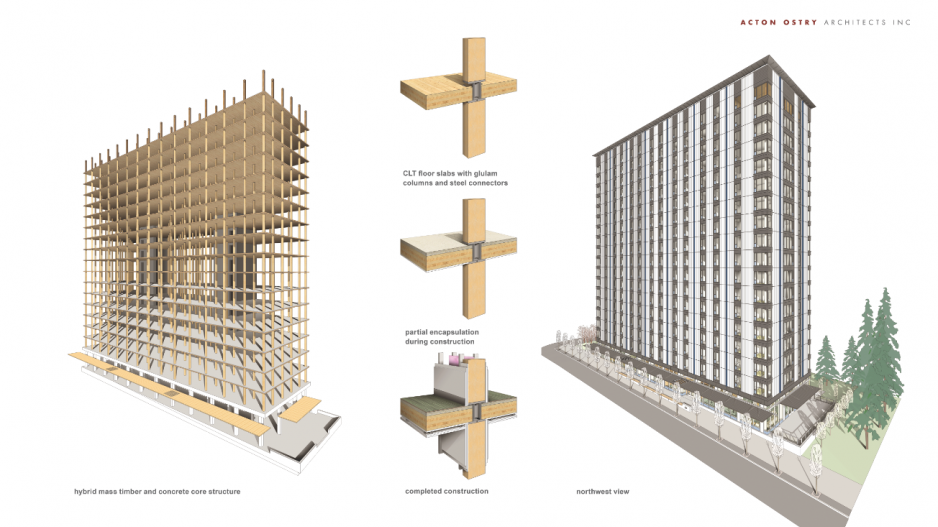

Fast + Epp is also the engineering firm for UBC’s new 18-storey student residence, which is now under construction.

“We are already working on projects in the U.S. as a follow-up on this project here,” said Bernhard Gafner, Fast + Epp’s project engineer on the UBC project.

The general public might be forgiven for thinking that the biggest engineering challenge in a tall wood building would be addressing the potential fire hazard. It’s not.

One of the biggest challenges, from an engineering standpoint, is getting approval from government and planning departments for a type of construction that is still in somewhat uncharted regulatory territory, Gafner said.

“Can you get the necessary approvals to build the building in a reasonable time frame? That’s the biggest challenge,” he said.

In UBC’s case, the B.C.building and safety standards branch helped expedite the building’s approval.

“The second challenge was economics – make sure that it can be built and delivered to the owner within the budget they have, within the time frame they have,” Gafner added.

Wood highrises are not built with the same kind of wood products used in single-family home construction.

Engineered wood products such as parallel strand lumber and cross-laminated, nail-laminated and glued laminated timber (glulam) are used.

Glulam is typically used for the beams, while cross-laminated timber is typically used for floors and walls.

Since these are large, dense blocks of wood, they don’t catch fire very easily, so the potential fire hazard is not as high as some might think. Also, all tall wood buildings are designed with sprinkler systems.

Similarly, the seismic hazard isn’t necessarily any more of a concern in an earthquake zone than it is with traditional steel and concrete buildings. Wood buildings have less mass. Less mass means less kinetic energy when the building is shaken by a tremor.

“If it’s lighter, you have much less force – that’s an advantage,” said Guido Wimmers, UNBC’s program chairman for the master of engineering in integrated wood design program.

The new 12-month course started in January. Only four students are enrolled, but not due to a lack of interest. There would have been more, but seven international students were unable to get a study permit in time for the

first one-year program.

“We’re quite confident that next year it’s going to be quite a bit more,” Wimmers said.

One of the engineering challenges in wood buildings is acoustics. Wood does not insulate sound as well as some other traditional materials, like concrete, so acoustics need to be addressed through design and engineering.

And unlike steel beams, wood beams can’t be welded, so connecting is another engineering approach that students learn.

Since the construction of highrises and infrastructure with wood is a relatively new field, there is a skills gap on the engineering side that UNBC hopes to address with its new master’s program.

“From our point of view, it needs more engineers in this area who have a much better understanding of what wood is capable of,” Wimmers said.

“There is this shift in industry. We have been doing relatively well in extracting natural resources and selling it across the world. That’s the stuff we can do and we did for a long time. We’re not good in sophistication in terms of what we can actually do with this. That’s what we’re addressing.

“We don’t have that industry yet. But it’s coming up and we want to support them.”

Eric Karsh, a principal with Equilibrium, welcomes the new engineering program.

“It’s multidisciplinary,” Karsh said. “It really takes the approach that the design of timber buildings has to be integrated. You need to not just know how to make things work structurally, but you need to understand acoustics, you need to understand fire protection, you need to understand how wood behaves during construction when it’s exposed to difficult climate.”

While projects like UBC’s new student residence are good showcases for design, engineering and construction capacity, Gafner believes the biggest market will be in the six-to-12-storey range.

His company is working with a developer on a proposed new 10-storey wooden office building in East Vancouver.

@nbennett_biv