In the movies, the goal behind firing bullets at a car’s fuel tank is to make it blow up.

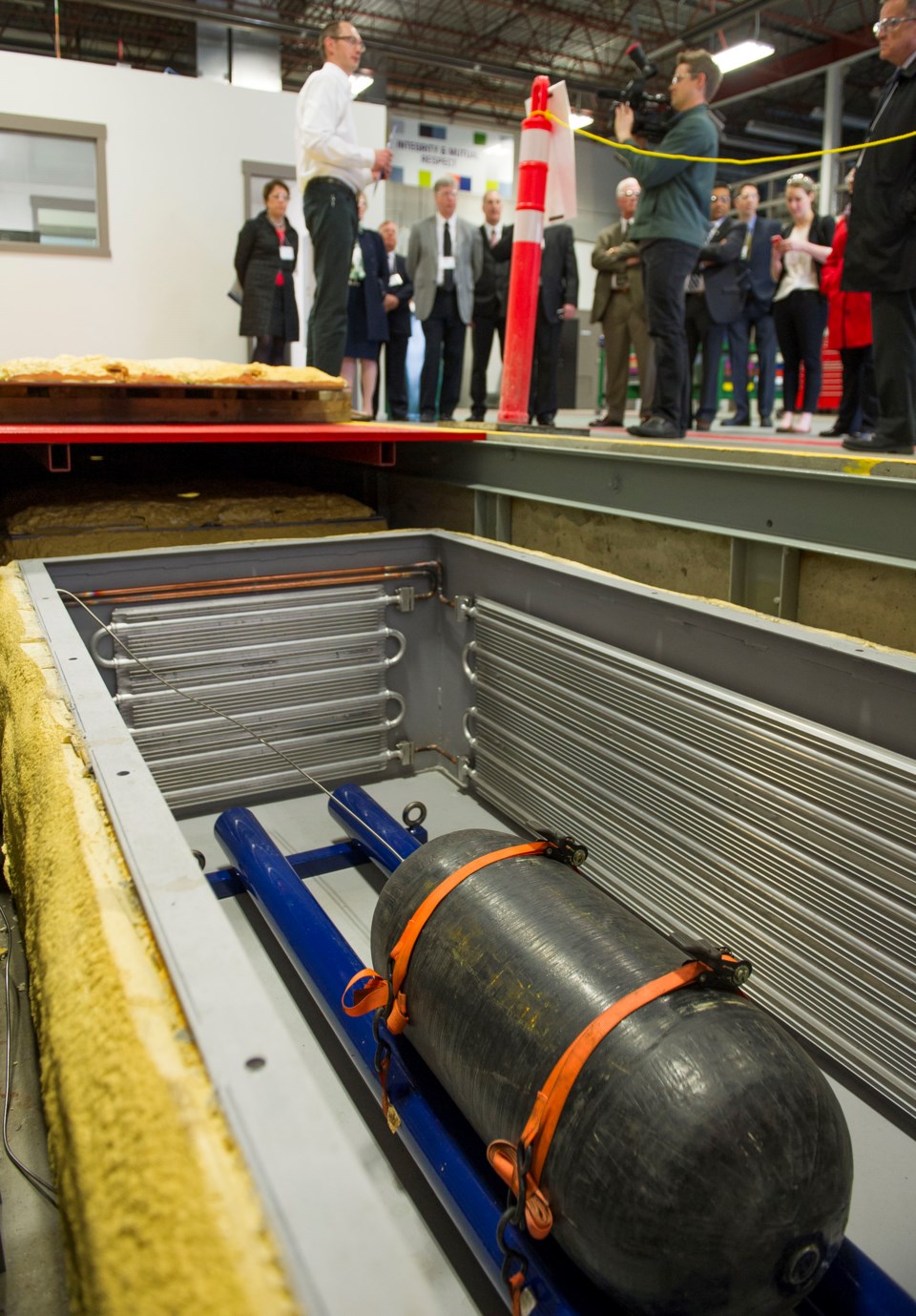

When researchers at the Canadian Standards Association’s (CSA) high-pressure-fuel-systems testing facility in B.C. unload a round of gunfire, the goal is to make sure the vehicle fuel systems they’re examining don’t explode.

“It’s quite an elaborate process that’s done to ensure safety of these components,” said Craig Webster, the CSA’s senior manager of transportation fuels, whose organization helps set regulatory standards and certifies products hitting Canadian markets.

“You have to subject it to things it would see in road service. You have to show temperature extremes, different road and automotive environments, vibration, fire.”

And yes, that even includes gunfire.

Prior to the April 28 opening of the CSA’s new 1,800-square-metre lab in Langley, the non-profit association did small amounts of testing at various facilities throughout the region and the world.

Vehicles using systems and components that run on alternative fuels, such as hydrogen fuel cells and compressed natural gas, benefit from getting a CSA certification when entering most markets in the world.

Although Metro Vancouver is not exactly the car capital of Canada, Webster said it makes sense to open a fuel-systems testing facility in the region.

“It came out of all the Ballards and other companies that were in the Vancouver area that are involved in supplying all these automotive-type markets, and they would need these testing services done,” he said.

“It was such a demand for this kind of testing done locally, it sort of grew here first in [the] Vancouver area, and then other companies from around the world say, ‘Man, we need that kind of testing done, too.’”

One of the driving forces behind the CSA’s new facility came in 2013, when the United Nations approved harmonized global technical regulations for hydrogen-powered cars.

“All these people who made [hydrogen-powered vehicles] previously didn’t have any standards to test to, but now they do. So now there’s a big demand for testing all these hydrogen fuel system components,” Webster said.

But the CSA isn’t the only local player on the scene.

Eric Denhoff, CEO of the Canadian Hydrogen and Fuel Cell Association, said many of the original equipment manufacturers his organization works with already test their systems and components at Surrey’s Powertech Labs, a subsidiary of BC Hydro.

“So Powertech and CSA are competitors essentially in the same market, which is great for us. We’ve got two places now here people can [test at],” he said.

Powertech senior manager of gas systems and engineering Philip Horacek said now that hydrogen-powered consumer vehicles are a reality in the marketplace, he expects demand to grow for the testing of high-pressure fuel systems.

“Up until two years ago, we were pretty much the only lab in the world that did what we did. There are other labs around the world now that are opening up that have similar capabilities to us,” he said, adding Powertech is taking a “wait-and-see” approach before considering any expansions at its own labs.

But Horacek added the relationship between Powetech and the CSA is more collaborative than anything else.

“Even though it appears, in terms of the lab space, CSA and ourselves have some overlapping markets, we do actually sit on a lot of CSA technical committees and help write the regulations they put out,” he said.

And, Horacek added, Powertech fires bullets at fuel systems, too.

@reporton