By taking advantage of cutting-edge technology, B.C. university students are building a brighter future, and at Emily Carr University of Art + Design, that future may soon be built by machines. Literally.

Emily Carr’s Material Matters project is a research and development program that explores the emerging medium and application of three-dimensional (3D) printing.

And 3D printing may be the future of British Columbia’s manufacturing industry.

“Manufacturing is the new sexy here in B.C.,” Kevin Davis, director of membership and strategic partnerships with Canadian Manufacturers and Exporters, said at Emily Carr earlier this month.

“Certainly we’re a resource-based economy [and] we’re developing into somewhat of a knowledge-based economy, but ultimately, we still need to make stuff.”

B.C.’s manufacturing sector brings in $18 billion in annual revenue and makes up 10% of the province’s exports. It provides 400,000 direct and indirect jobs, as well as $8.6 billion in wages.

Vancouver-based Rayne Longboards has been researching the potential of 3D technology since last year.

“When you get something from a factory or a contractor, they’re going to give you something that they think you want, and it might not be exact,” said Graham Buksa, Rayne’s design director and CEO.

Since getting involved with 3D printing, Rayne Longboards has been able to produce moulds cheaper and faster than was previously possible.

“We’re production-ready in three days,” Buksa said. “If someone orders something and it’s not on the shelf, we can just walk into the shop and make it – make a hundred of them, make a thousand of them.”

The facilities at Emily Carr on Granville Island are state-of-the-art, and an entire building is devoted to housing warehouses of ceramic and polymer student projects, kilns and printing equipment.

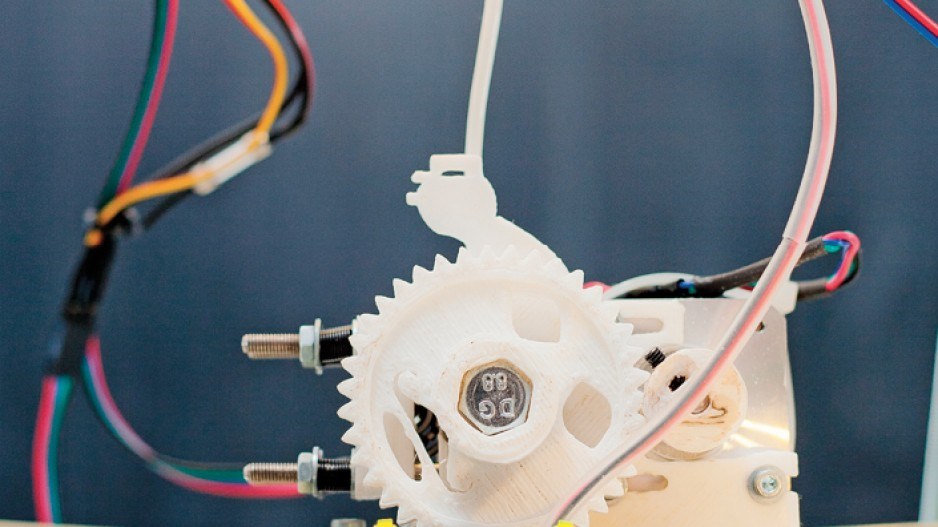

The printers themselves come in all shapes and sizes. There are shelves of MakerBot Replicators, a line of consumer-grade 3D printers that print up to 410-square-inch objects, as well as large oven-style printers that can produce larger pieces for assembly of furniture or machine parts.

With the ability to accept common 3D design files like STL (stereolithography), and consumer models starting at around $2,000, 3D printing is poised to make an impact in the commercial space. As schools like Emily Carr have begun offering in-depth programs dedicated to teaching the skills and knowledge necessary to take advantage of the technology, the future is just around the corner. And getting there might just be a matter of hitting “print.” •