Self-cleaning cameras for heavy industries, dual--fuel engines that burn low-emission hydrogen, high-tech sensors and big-data analysis that prescreen ore at mine sites – these are just some of the innovations that B.C.’s clean--technology sector has produced in recent years, thanks to traditional natural resource industries like mining, forestry and oil and gas.

These industries by nature have problems, many of them environmental, that have provided B.C.’s tech sector with opportunities to develop new technologies, some of which are now being exported.

One of the local companies tapping into the international market is MineSense Technologies, which, backed by Vancouver clean-tech venture capital firm Chrysalix, not only is now in commercial mode, but also is expanding into Chile.

The company recently signed its first commercial contract with a B.C. copper miner to install its technology, which uses sensors and big-data analysis to pre-screen ore for higher mineral content, which reduces waste and costs.

Last week, the company secured $19 million in venture capital funding, led by Aurus Ventures, a Chilean venture capital firm, and is now working on its second commercial contract with a copper mine in Chile. It recently opened an office there.

Far from being a threat to traditional industries like mining, forestry and oil and gas, B.C.’s clean-tech sector thrives on those sectors, because they provide a practically endless supply of engineering and environmental problems for it to solve.

“There’s tremendous opportunity in some of the very large existing industries to make them more efficient – both economically efficient but also more environmentally efficient,” said MineSense CEO Jeff More.

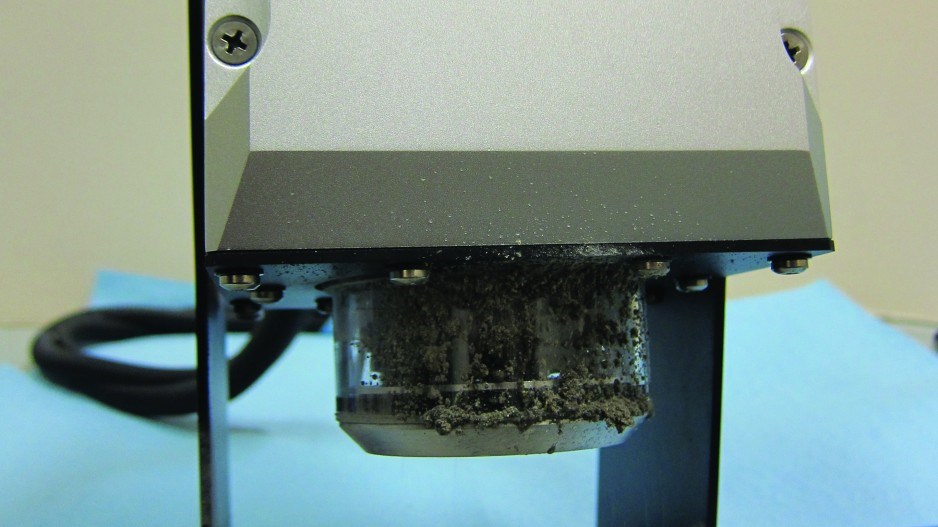

ExcelSense Technologies has also created technology that could have significant export potential. The company developed a self-cleaning camera that is designed for harsh environments, with a special lens coating that helps repel debris. If the lens does become dirty, optical sensors will detect it and the camera will automatically withdraw into its sleeve before re-emerging clean.

Cameras are already used in a wide range of resource-based industries from sawmills to mining operations. These cameras can become covered with dust, mud, grease, oil and other types of debris. Cleaning them can be a constant challenge.

“You have the ability to deploy these cameras in situations where you would have needed constant maintenance and cleaning,” said ExcelSense CEO Nima Nabavi. “Through this technology, you install the camera and you forget about it.”

ExcelSense is one of three B.C. companies that recently were awarded close to $1 million worth of grants through the BC Innovation Council’s (BCIC) Ignite fund. The grants are intended to help new companies commercialize their products.

“It basically has to be commercialized within three years,” BCIC CEO Carl Anderson said. “It has to have a market and it has to have an industry component that matches in.”

This year’s Ignite award funding totals $873,475. To qualify, the three recipients had to come up with two-thirds matching funding from industry partners, which brings the total to $2.6 million for the three companies.

The idea behind the award is twofold: provide clean-tech start-ups with a boost, and bring more innovation into resource-sector industries with made-in-B.C. technology.

“What you’re trying to do is use that applied research to solve an industry problem which is building a market,” Anderson said. “You’re meeting a known need – something they’re trying to fix.”

Other recipients in the latest round of Ignite award funding are Hydra Energy and Axine Water Technologies.

Axine developed an electrochemical processes for treating contaminated water from the oil and gas sector. It is now working with researchers at the University of Victoria on a process that will enhance the process’ ability to remove ammonia from industrial waste water.

Hydra Energy, meanwhile, developed technology that can convert diesel engines for large fleet trucks so that they can run on either diesel or hydrogen, or a blend of both. Since hydrogen contains no carbon atoms, burning it produces no carbon dioxide emissions.

It’s Hydra Energy’s business model that sets it apart. Hydra covers the cost of converting the trucks’ engines, installing hydrogen fuel tanks and providing the fuelling infrastructure. In exchange, the companies using the technology sign long-term contracts to buy their hydrogen fuel from Hydra for a fixed rate.

“The advantage is that you get to cut operating costs and emissions for no upfront costs,” said Simon Pickup, Hydra Energy’s co-founder and CEO.

Although the companies are working on projects that solve problems for B.C. businesses, it’s expected that the technology will have wider applications that can eventually be exported, Anderson said.

“Just about everything can go worldwide.”